Microsoft introduces MatterSim: Revolutionizing materials simulation and design

Understanding materials under realistic conditions becomes easy

3 min. read

Published on

Read our disclosure page to find out how can you help Windows Report sustain the editorial team Read more

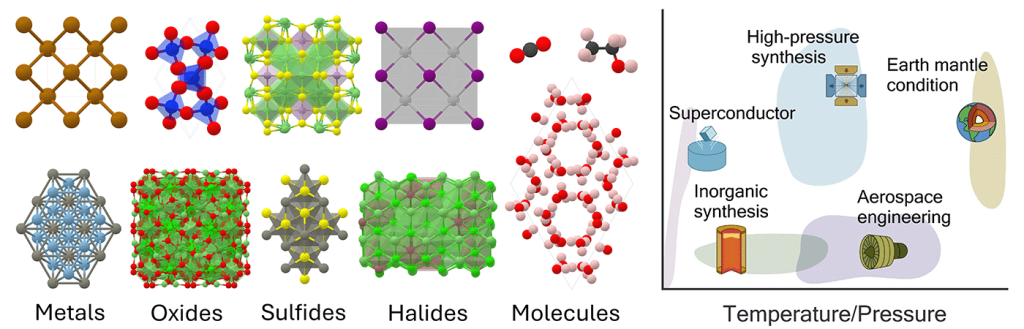

Microsoft Research team developed MatterSim, an innovative deep-learning model for accurate and efficient materials simulation and property prediction over a broad range of elements, temperatures, and pressures, to enable in-silico materials design.

The team included four people, Han Yang, Senior Researcher Jielan Li, Researcher 2 Hongxia Hao, Senior Researcher Ziheng Lu, Principal Researcher

How does MatterSim help?

Accurate and comprehensive simulation

MatterSim uses deep learning to comprehend atomic interactions on the basis of fundamental principles of quantum mechanics

It covers an extensive range of elements and conditions, spanning from 0 to 5,000 Kelvin (K) and from standard atmospheric pressure to 10,000,000 atmospheres.

Microsoft mentioned in the blog:

In our experiment, MatterSim efficiently handles simulations for a variety of materials, including metals, oxides, sulfides, halides, and their various states such as crystals, amorphous solids, and liquids. Additionally, it offers customization options for intricate prediction tasks by incorporating user-provided data.

Uses large-scale synthetic data

The model’s learning foundation is based on large-scale synthetic data generated via a combination of generative models, active learning, and molecular dynamics simulations.

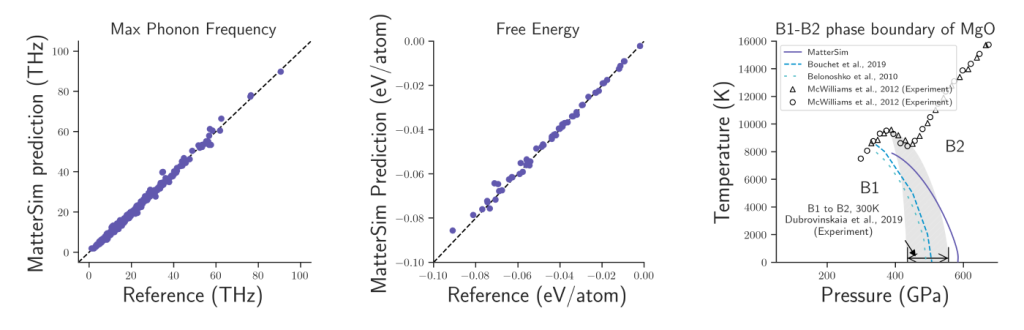

This approach ensures comprehensive coverage of material space, enabling MatterSim to predict energies, atomic forces, and stresses. It functions as a machine learning force field, boasting an accuracy level on par with predictions derived from first principles.

Furthermore, MatterSim attains ten times more accuracy than the previous state-of-the-art models in terms of material property predictions at finite temperatures and pressures.

Adaptable design & has high data efficiency

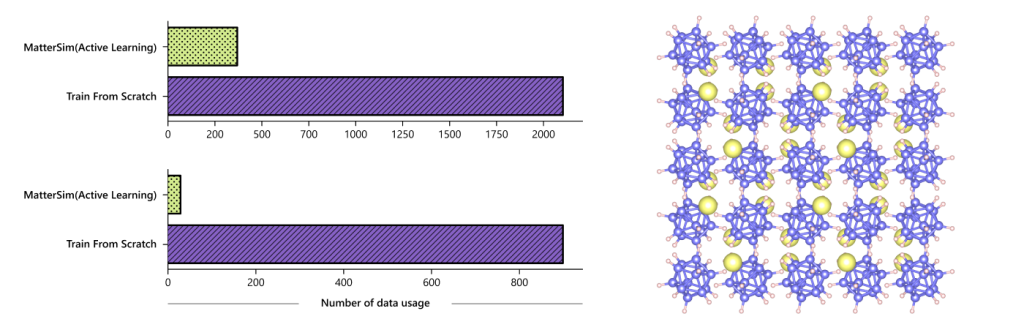

As MatterSim is trained on broad synthetic datasets, it can adapt to specific design requirements by adding additional data.

With active learning and fine-tuning, it can customize predictions with high data efficiency. Compared to conventional methods, the model only needs 3% of data to match experimental accuracy and versatility.

Narrowing the gap between Models and Real-World Measurements

Decoding material properties from atomic structures is complicated and challenging if done using existing statistical methods like molecular dynamics.

MatterSim addresses this by mapping these relationships directly via machine learning. The model has custom adaptor modules that refine it, allowing it to predict material properties without requiring intricate simulations.

How MatterSim can be useful?

MatterSim can be beneficial in a lot of ways:

- Accurate – Offers high accuracy in predicting material properties, thereby ensuring reliable simulation results and helping informed decision-making.

- Versatile – Can simulate materials across various elements, temperatures, and pressures, allowing you to explore various material compositions and conditions.

- Efficient – Allows faster experimentation and iteration, thereby saving time and resources in the materials design process.

- Customization – Offers customization options for intricate prediction tasks by incorporating user-provided data.

- Streamlined workflow – Simplifies the translation of material properties from structural data, thereby eliminating the requirement of complex simulations.

What is the future?

As the research progresses, Microsoft plans to shift its focus towards experimental validation to reinforce its potential role in pivotal sectors, including the design of catalysts for sustainability, energy storage breakthroughs, and nanotechnology advancements.

The integration of MatterSim with generative AI models and reinforcement learning signifies a transformative shift in the methodical generation of innovative materials customized to meet a wide range of applications.

Furthermore, this advancement ensures speed-up material development and sustainable industrial practices, thereby addressing critical challenges in the materials engineering industry.

What do you think about this development? Share your opinions with our readers in the comments section below.